Schedule for Demo

Learn More

8700-211-262

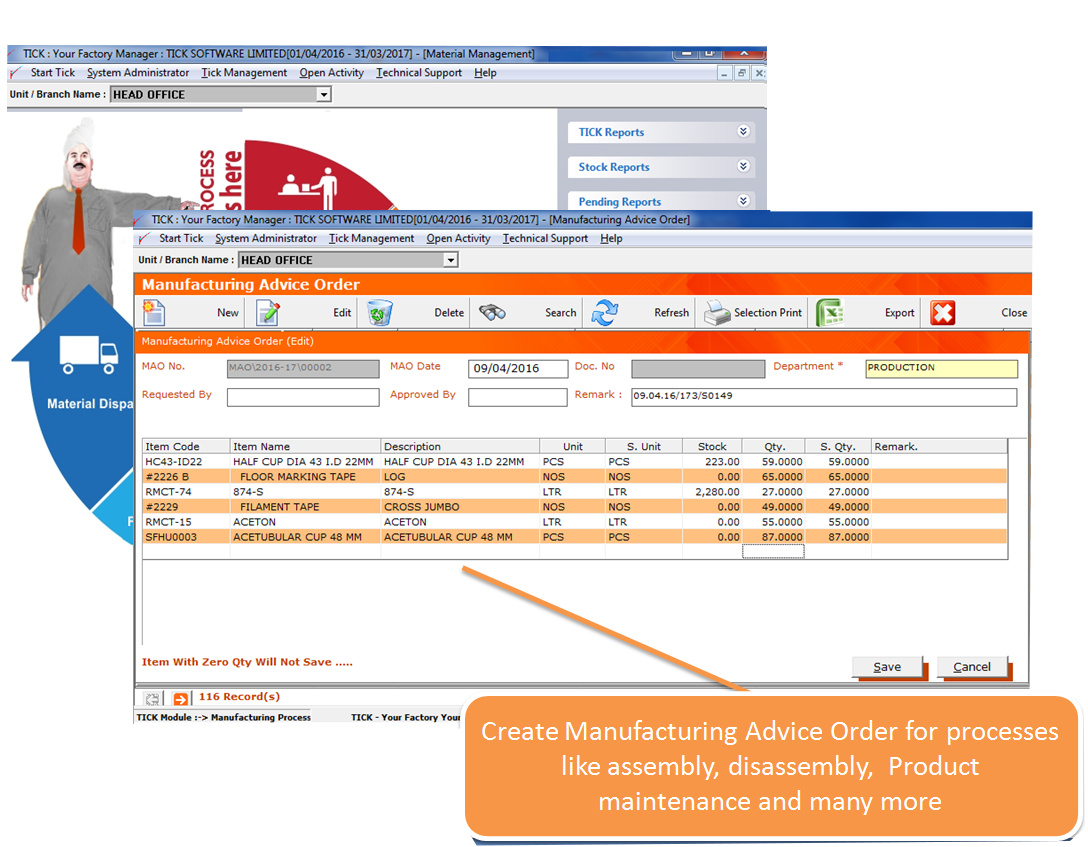

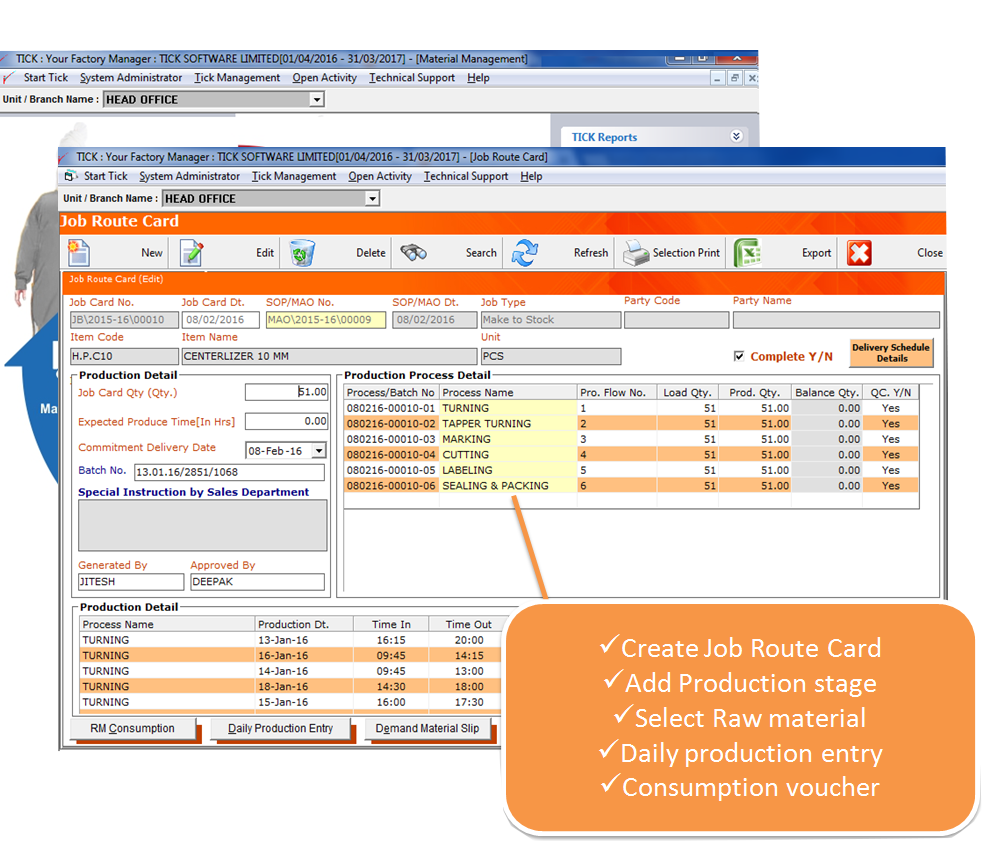

TICK offers advanced work orders, manufacture orders, bills of materials, and other tools you need to maximize efficiency in your production process. Whether you have simple or more complex manufacturing needs, TICK Manufacturing is a great solution for you.

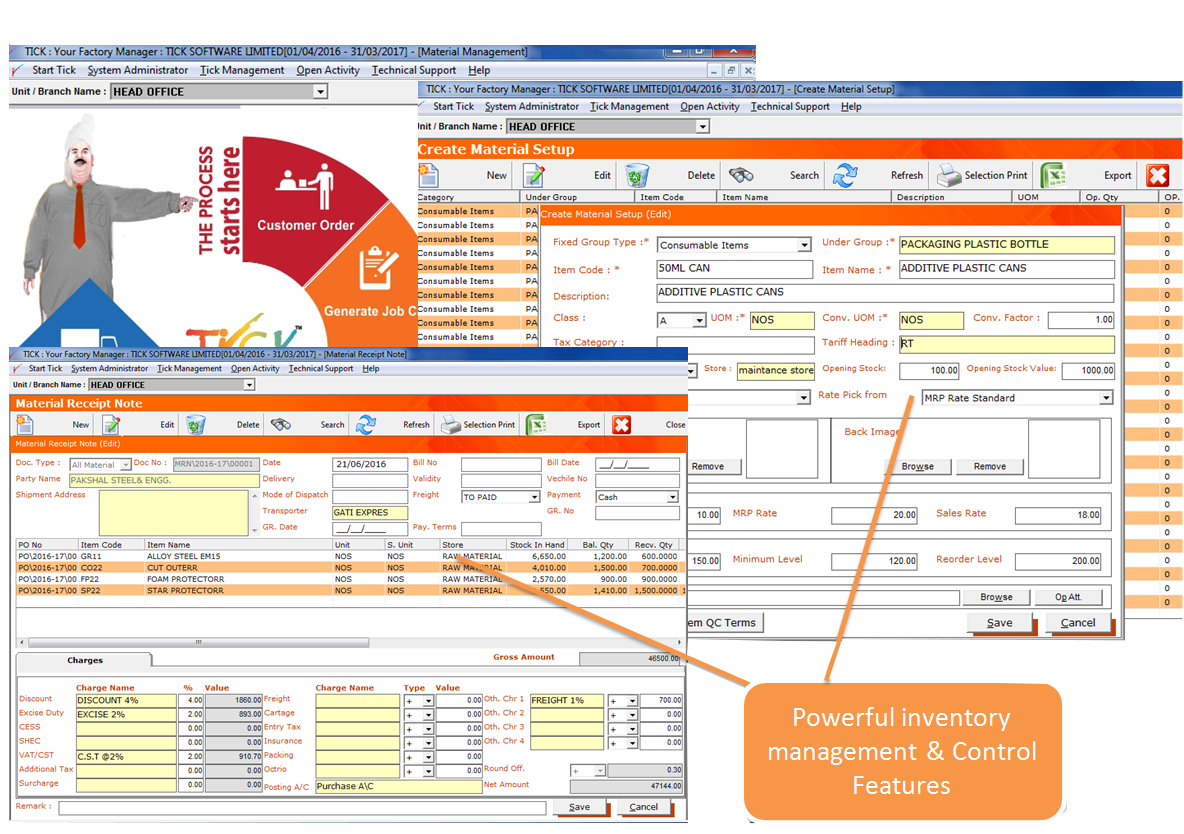

Inventory management is a critical part of every business. TICK provides powerful inventory management features to help your business manage multiple warehouses, track shipments, automatically reorder products, Stock Transfer to Locations and much more.

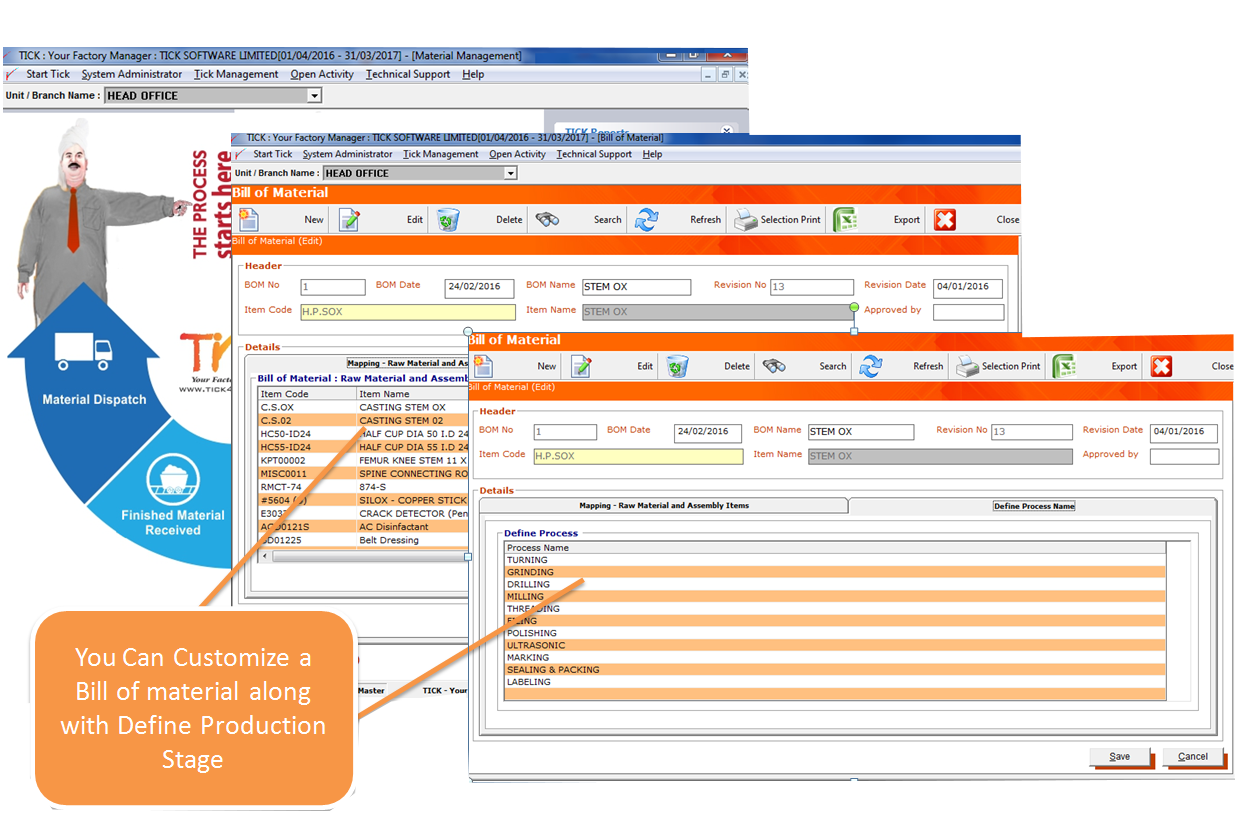

After you create a bill of materials in TICK you can save it for future use. So if you have a popular product you can simply replicate the appropriate bill of materials each time you need more of it. This makes the manufacturing process faster by keeping the instructions always close at hand.

TICK is an ideal inventory solution for many types of manufacturers. It allows you to create both simple and complex Job Cards for a variety of tasks. You can also group multiple Job Card into overarching manufacture orders to streamline production and establish accountability at each step of the manufacturing process.

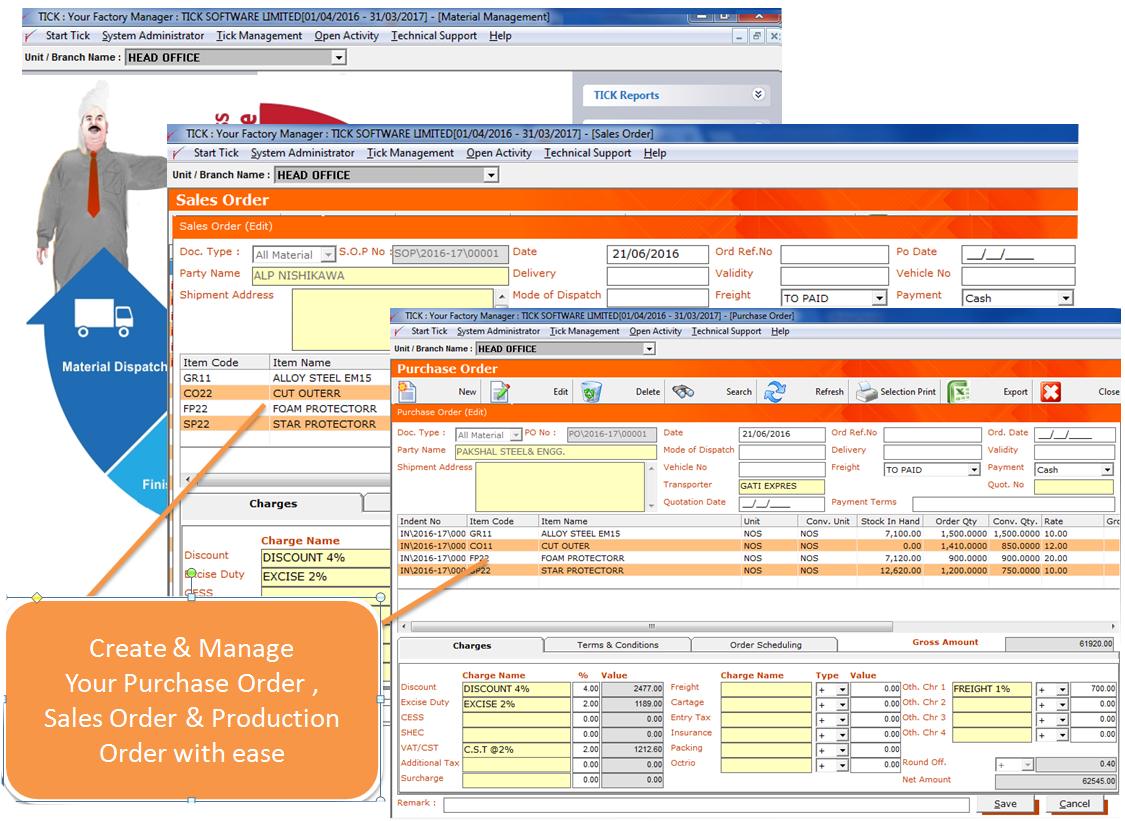

Generating purchase orders, sales orders & Job work orders with TICK. TICK smooths out the order management process so every step of the way you are in control of your inventory and have the information you need to make informed ordering decisions.

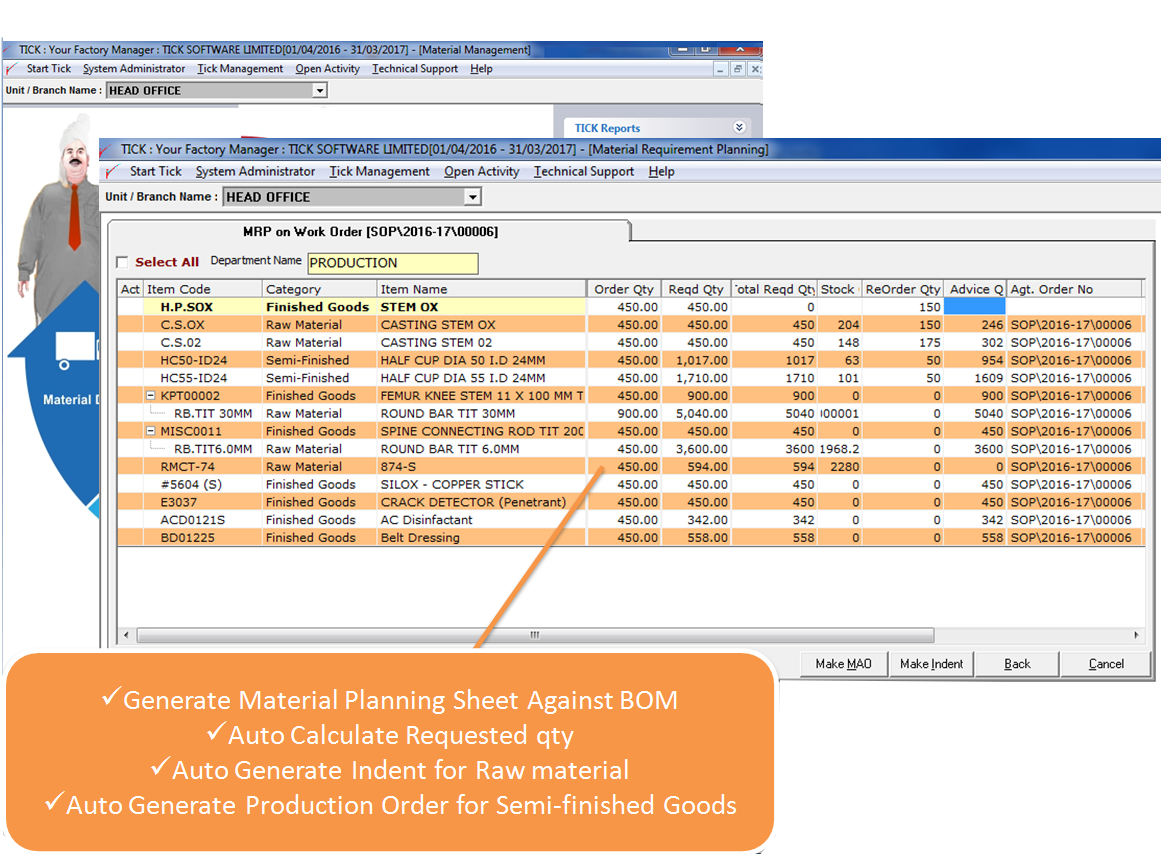

Material requirements planning (MRP) is a production planning and inventory control system. An MRP integrates data from production schedules with that from inventory and the bill of materials (BOM) to calculate purchasing and shipping schedules for the parts or components required to build a product.

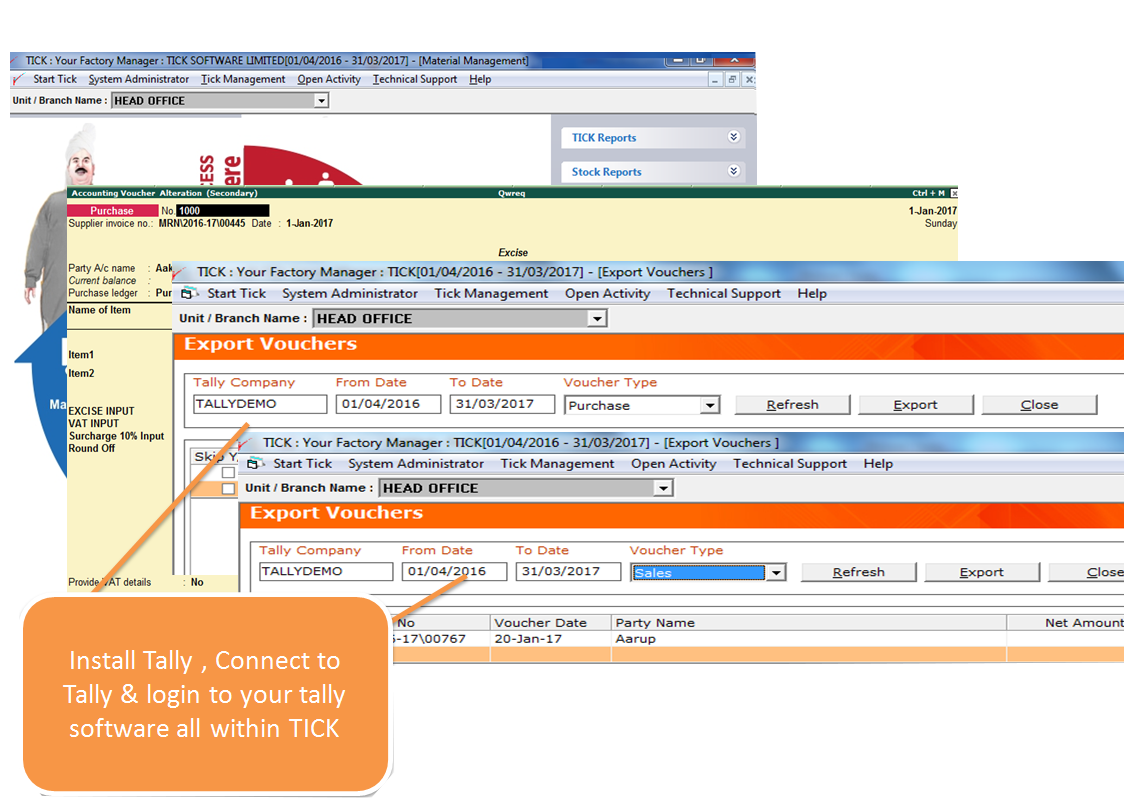

TICK integrates seamlessly with every version of Tally. Tally is a useful accounting solution, but it can't handle inventory management for manufacturing units tasks like Raw Material to Finish goods, part tracking, advanced bill of materials, MRP and job card. TICK can do these things and many others.

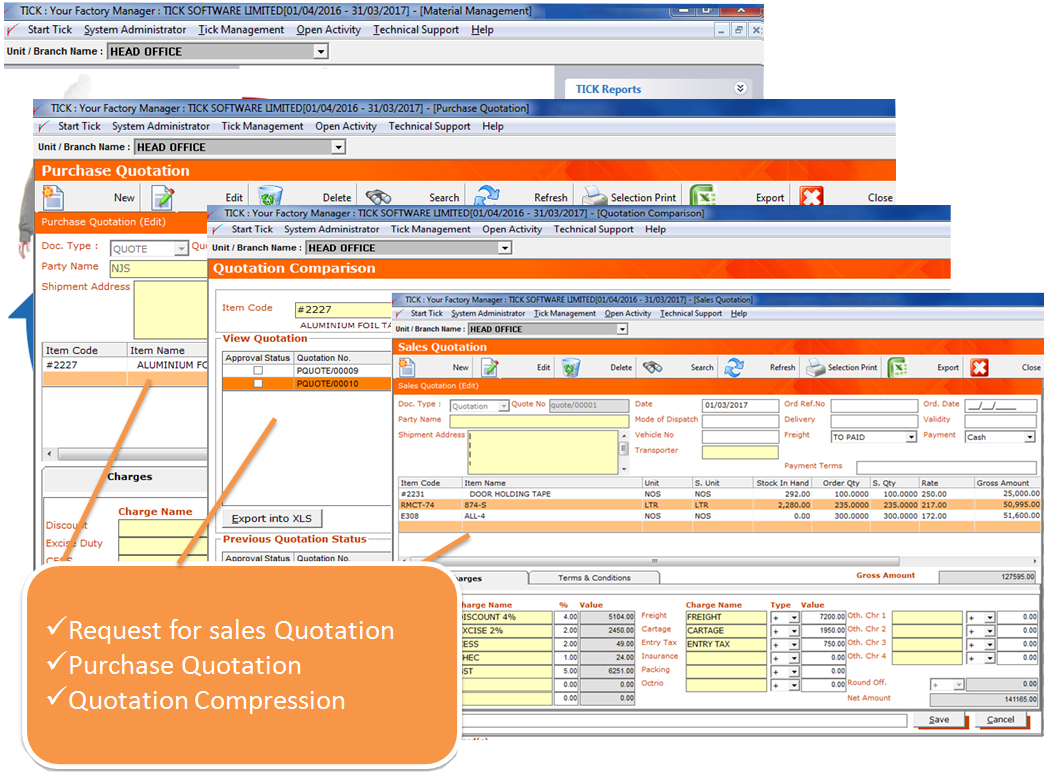

A Quotation is interesting when you have never purchased the products with that supplier before and therefore don't know their price. It is also useful if you want to challenge your suppliers once you have a well-established relationship with them. You can also use it to assess the cost of a project and see if it makes it feasible.

Flexible and feature rich quoting helps to convert sales activities into sales orders. TICK allows the creation of sales quotations, estimates and sales proposals in a faster manner with 100% accurate data. It is possible to enter customer details or retrieve the same from existing data sets. Similarly, products can be added and categorized or retrieved from a pre-existing source. While preparing sales quotations, it is possible to add items from pre-existing quotations which may be categorized. The TICK provides a predefined set of templates to enable you to prepare quotations estimates and sale proposals easily.

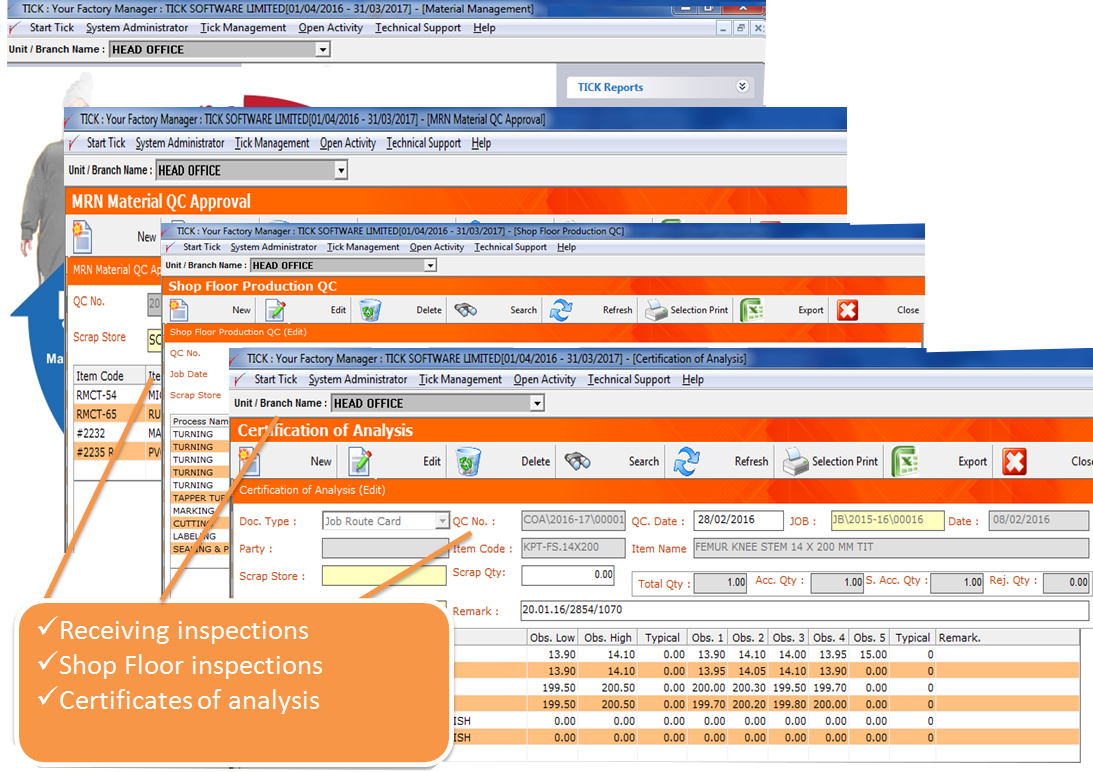

TICK has a feature of inspecting goods (Production, purchase and store department) with our quality control module helps a business keep a track of its quality levels at various stages. Thus helping it to detect the quality variance at initial stages, initiate rectification procedures and reduce wastages.

Installing TICK quality control module is like taking a step ahead to improve quality control across your entire organization.

1207 Pragati Tower, 26, Rajendra Place, New Chennai-110008, India

sales@ticksoftwares.in

+91-87-00-211-262

@ticksoftwares

© TICK SOFTWARES LIMITED. All right reserved. CRM Login

CIN : U72300DL2015PLC279192, GSTIN : 07AAFCT3112Q1Z4, PAN : AAFCT3112Q